Minebea Intec PR 5410/03 Installationsanleitung

- Typ

- Installationsanleitung

PR5410/03 Installation Manual

9499 050 54304 11/09/2018 Page 1 of 7 pages

Electrical apparatus for

installation in Zone 2 and 22

explosion-hazarded areas

Device type: Indicator for installation by the customer

Type number: PR5410/03

Manufacturer: Minebea Intec GmbH

Standards: EN 60079-0: 2006 Gas: General requirements

EN 60079-15:2005 Protection type “n“

EN 61241-0: 2006 Dust: General requirements

EN 61241-1: 2004 Protection by enclosures “tD“

Content:

1. General description

2. Protection concept

3. Verification of compliance with EN 60079-15:2005

4. Verification of compliance with EN 50281-1-1:1998

5. Tests

6. Internal production control according to Directive 94/9/EC

7. Documentation

PR5410/03 Installation Manual

9499 050 54304 11/09/2018 Page 2 of 7 pages

1. General description

The PR5410/03 indicator is intended for installation by the customer, and is based on the

PR5410/96 or PR5410/97 indicator certified for use in Zones 2 and 22.

As a Category 3 electrical apparatus, the PR5410/96 or PR5410/97 indicator is suitable for

installation in Zone 2 and Zone 22 explosion-hazarded areas according to the

SAG.09.ATEX002 test report. This indicator comprises an IP54-protected stainless steel

housing with a built-in PR5410/01 indicator.

The PR5410/01 indicator meets the relevant requirements for Zones 2 and 22. However,

an additional enclosure is required for compliance with protection class IP54.

To install the PR5410/01 indicator in an enclosure, the retainer profiles must be shortened.

When mounted in an enclosure, the indicator type description is PR5410/03. Moreover, the

indicator is delivered with the 940515410979-511 mounting accessories. For installation,

refer to installation drawing 940515410979-510.

1.1 Assembling a customer-specific indicator with PR5410/03

Installation in Zone 22 with conducting dusts is not permissible.

Permissible ambient temperature -10 °C ... +40 °C, provided that the enclosure supplied by

the customer is permissible for this temperature range.

If the requirements mentioned under item 1.4 are met, the resulting product can be marked

as follows:

II 3G Ex nA II T4 X

II 3D Ex tD A22 IP5x T80°C X

The safety information according to drawing 940515410979-460, revision 02, must be

adapted and extended by the manufacturer of the final product and delivered with the

product.

1.2 Standards

1.2.1 Standards for explosion protection

EN 60079-0: 2006 Gas: General requirements

EN60079-15:2005 Protection type “n“

EN 61241-0: 2006 Dust: General requirements

EN 61241-1: 2004 Protection by enclosures “tD“

1.2.2 Compliance with other standards

The device must meet the requirements of EN 61010-1 for electrical safety.

Moreover, the legal EMC requirements must be met.

PR5410/03 Installation Manual

9499 050 54304 11/09/2018 Page 3 of 7 pages

1.3 PR5410/03 indicator

1.3.1 General

The indicator is suitable for connection to 24 V DC (

±

20%) supply. Power consumption is

approx. 11 W.

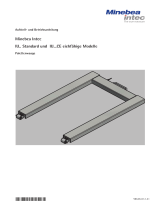

Fig. 1: PR5410/03 indicator

The PR5410/03 indicator has a metal housing (aluminium profiles and galvanized sheet

steel). The (foil-covered) aluminium front panel is nearly 4 mm thick. The keypad and

display area is recessed, i.e. the impact test with reduced energy is passed.

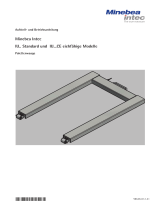

Fig. 2: PR5410/03 indicator, reinforcing frame and retainer profile

Reinforcing frame

Retainer profile

PR541/03 indicator

PR5410/03 Installation Manual

9499 050 54304 11/09/2018 Page 4 of 7 pages

Fig. 3: Power supply connector on PR5410/03 indicator with fuse holder

Fig. 4: Connectors on the rear of the PR5410/03 indicator housing

1.3.2 Internal construction of the PR5410/03 indicator

The internal construction of the PR5410/03 indicator meets the relevant requirements of

the standards for installation in Zone 2 and Zone 22:

EN 60079-0: 2006 Gas: General requirements

EN60079-15:2005 Protection type “n“

EN 61241-0: 2006 Dust: General requirements

EN 61241-1: 2004 Protection by enclosures “tD“

1.3.2 Installation of the PR5410/03 indicator in an enclosure according to drawing

940515410979-510

Unscrew and remove the retainer profiles from the indicator. Fit the gasket (included in

mounting kit 940515410979-511) to the rear of the indicator front panel to ensure a tight

seal. Insert the indicator through the cutout in the enclosure front panel from the front. Slide

the reinforcing frame (included in mounting kit 940515410979-511) over the indicator from

the rear and push it fully home against the enclosure front panel. Remount the two retainer

profiles, and tighten the screws so that the reinforcing frame presses the indicator front

panel against the enclosure front panel.

Indication of fuse rating

Fuse holder

Load cell

connector

PR5410/03 Installation Manual

9499 050 54304 11/09/2018 Page 5 of 7 pages

1.4 Requirements for an enclosure for indicator PR5410/03

The construction of the enclosure including its cable glands and final product testing fall

within the sole responsibility of the final product manufacturer.

Several requirements which must be met are listed in the following paragraphs, however,

without claiming to be complete.

The enclosure must have characteristics that ensure protection class IP54. For this, we

recommend using a stainless steel enclosure with a minimum wall thickness of 1 mm.

Mount a front door firmly to the enclosure by means of hinges. Opening this door must be

possible only using tools.

If a plastic enclosure is used, make sure that the enclosure is electrostatically conducting

and chemically, thermally and mechanically resistant.

Equipotential bonding can be provided by means of the mounting elements or via an

internal grounding terminal (connector). All parts (door, enclosure) are interconnected via a

grounding cable and are thus connected to the equipotential bond.

All cable glands must meet the requirements for IP54. They must be suitable for a

temperature range from -15 °C to +80 °C and have ATEX approval1 .

We recommend using a venting device, e.g. type DAE M12 SS supplied by

Weidmüller GmbH & Co. KG. It is made of stainless steel and meets the

requirements for IP66, 68 and 69K. The venting device is suitable for a

temperature range from -40°C to +120°C.

The internal wiring of the outer enclosure is by means of screws, or is interlocked. Gaskets

must be suitable for a minimum continuous operating temperature of 80 °C and chemically

resistant. The final customer must be informed accordingly.

Installation of the PR5410/03 indicator in the enclosure must be done by the manufacturer

of the final product in accordance with drawing 940515410979-510, revision 01. Use of the

940515410979-511 mounting accessories supplied by Minebea Intec is mandatory.

1 E.g. cable gland “blueglobe® Ex e II“ from PFLITSCH GmbH & Co. KG: ”II 2 G/D, Ex e II“; PTB 06 ATEX 1036

X, IP 68; brass, nickel-plated; M16: art. no. bg 216msex; M20: art. no. bg 220msex. Temperature range of the

inserted gasket: -40 °C to +105 °C. Alternatively: Perfect*** type cable gland from Jacob GmbH; DMT 99

ATEX E 016 (4th supplement); II 2G Ex e / II 2D Ex td A21 IP68; temperature range -20°C ... +80°C.

PR5410/03 Installation Manual

9499 050 54304 11/09/2018 Page 6 of 7 pages

2. Notes on the protection concept

2.1 Dust explosion protection

The requirements for Zone 22 acc. to EN 61241-0: 2006 and EN 61241-1: 2004 are

met:

2.1.1 The indicator enclosure must provide at least IP65 protection. In general, the required

mechanical strength is provided by the metal housing. The non-metal parts (foil-covered

keypad) pass the impact test (1 kg from a height of 0.7 m). All introduced cables must pass

the traction test of 100 N (10 kg) during 6 h (elongation <6 mm).

2.1.3 During normal operation under maximum load and at a maximum ambient temperature of

+40 °C, the surface temperature of the PR5410/03 indicator is below 55 °C and therefore

less than 60 °C (5 K safety margin). Consequently, T80 °C is met.

2.1.2 The continuous operating temperatures of gaskets, cable glands and venting device must

be at least 10 K higher than the maximum housing temperature at maximum permissible

ambient temperature, i.e. min. 70 °C.

2.1.4 Grounding (connection of an equipotential bonding conductor) must be done via a screw or

mounting element fitted in the enclosure.

2.1.5 To prevent ignition due to an electrostatic charge, the surface of the foil-covered keypad is

less than 180 cm² and surrounded by a grounded frame. Moreover, the thickness of the

polyester foil is limited to 180 µm and the foil-covered keypad is bonded to the grounded

front panel. I.e. electrostatic discharge is ensured. Moreover, the keypad is not exposed to

permanent friction, so there is no risk of dust explosions.

2.2 Gas explosion protection

For Zone 2, the following additional requirements of EN 60079-15:2005 are

applicable:

2.2.1 The indicator does not contain spark-emitting components. The device meets protection

type Ex nA. An exception is the keypad, which contains an energy-limited Ex nL-compliant

circuit.

2.2.2 The device is considered as voltage and power-limited (≤30 V; 11 W). Transient voltage

effects are prevented. This means that Chapters 6.7 (air gaps, leakage paths and

distances) and 6.8.2 (insulation between conducting parts) of standard EN60079-15:2005

need not be taken into account due to Chapter 23 of EN60079-15:2005.

2.2.3 All cables (except 24 V DC supply cable) are data signal leads. I.e. no transient voltage

needs to be taken into account for these cables.

2.2.4 The built-in battery is of type 1 and meets the requirements of Chapter 22 of

EN 60079-15:2005.

2.2.5 The keypad is classified as Ex nL (energy-limited circuit).

2.2.6 All circuit boards are mounted firmly with screws.

2.2.7 The interface cards contain only nA circuits. No transformers, batteries, relays or other

spark-emitting or voltage-generating components are fitted on the cards. High-impedance

connections (Ex nL circuits) are used for the coding switches). Components must be

dimensioned so that no temperature increase above 80 °C can occur during normal

operation. The equipment connected via the data cables only supplies voltages and

currents that meet the requirements according to Chapter 23 of EN60079-15:2005.

2.2.8 To prevent ignition due to electrostatic charges, the surface of the foil-covered keypad is

less than 180 cm² and surrounded by a grounded frame. Moreover, the thickness of the

polyester foil is limited to 180 µm and the foil-covered keypad is bonded to the grounded

front panel. Thus, group IIC gases are permissible.

2.2.9 Safety reserves are provided.

PR5410/03 Installation Manual

9499 050 54304 11/09/2018 Page 7 of 7 pages

3. Verifying compliance with EN 60079-15:2005

Compliance of the PR5410/03 indicator with EN 60079-15:2005 is confirmed by Minebea

Intec GmbH. If the measures mentioned in Chapter 2.2 are taken and mounting is done in

accordance with 1.3.2, the manufacturer of the final product can create the conformity

declaration.

4. Verifying compliance with EN 50281-1-1:1998

Compliance of the PR5410/03 indicator with EN 50281-1-1:1998 is confirmed by Minebea

Intec GmbH. If the measures mentioned in Chapter 2.2 are taken and mounting is done in

accordance with 1.3.2, the manufacturer of the final product can create the conformity

declaration.

5. Tests

The tests required for the enclosure by the standards mentioned under 3. and 4. must be

carried out by the manufacturer of the final product.

6. Internal production control according to Directive 94/9/EC

The manufacturer of the final product must perform internal production control in

accordance with Annex VIII of Directive 94/9/EC.

7. Documentation

The product must be delivered with an operating manual which contains all safety-relevant

information.

As the device is marked with “X“, it must be supplied with an EC conformity declaration

containing the technical data and reference to the safety information.

The safety information acc. to drawing 940515410979-460, revision 02 must be adapted

and extended by the manufacturer of the final product and delivered with the product.

Published by

Minebea Intec GmbH | Meiendorfer Strasse 205 A | 22145 Hamburg, Germany

Phone: +49.40.67960.303 | Email: [email protected]

www.minebea-intec.com

Installationsanleitung PR5410/03

9499 050 54304 09.11.2018 Seite 1 von 7 Seiten

Elektrisches Betriebsmittel zum

Einsatz in explosionsgefährdeten

Bereichen der Zone 2 und 22

Geräteart: Indikator für den Selbsteinbau

Gerätetyp: PR5410/03

Hersteller: Minebea Intec GmbH

Normen: EN 60079-0: 2006 Gas: Allgemeine Anforderungen

EN 60079-15:2005 Zündschutzart „n“

EN 61241-0: 2006 Staub: Allgemeine Anforderungen

EN 61241-1: 2004 Schutz durch Gehäuse „tD“

Inhalt:

1. Allgemeine Beschreibung

2. Schutzkonzept

3. Verifizierung der Übereinstimmung mit EN 60079-15:2005

4. Verifizierung der Übereinstimmung mit EN 50281-1-1:1998

5. Prüfungen

6. Interne Fertigungskontrolle gemäß Richtlinie 94/9/EG

7. Dokumentation

Installationsanleitung PR5410/03

9499 050 54304 09.11.2018 Seite 2 von 7 Seiten

1. Allgemeine Beschreibung

Der Indikator PR5410/03 ist bestimmt für den Selbsteinbau durch den Kunden und basiert

auf den für Zone 2 und Zone 22 zulässigen Indikator PR5410/96 bzw. PR5410/97.

Der Indikator PR5410/96 bzw. PR5410/97 ist als elektrisches Betriebsmittel der Kategorie

3 gemäß Prüfbericht SAG.09.ATEX002 geeignet für den Einsatz in explosionsgefährdeten

Bereichen der Zone 2 und 22. Dieser Indikator besteht aus einem IP54-dichten Edelstahl-

gehäuse mit eingebautem Indikator PR5410/01.

Der Indikator PR5410/01 erfüllt die relevanten Anforderungen für Zone 2 und 22, benötigt

aber noch ein zusätzliches Umgehäuse, um IP54 zu erfüllen.

Für den Einbau des Indikators PR5410/01 in ein Umgehäuse werden die Haltebügel ge-

kürzt und der Indikator dann mit PR5410/03 bezeichnet. Ferner wird das Montageset

940515410979-511 mitgeliefert. Der Einbau hat gemäß Einbauzeichnung

940515410979-510 zu erfolgen.

1.1 Aufbau eines kundenspezifischen Indikators mit PR5410/03

Der Einsatz in Zone 22 mit leitfähigen Stäuben ist nicht statthaft!

Zulässige Umgebungstemperatur -10 °C ... +40 °C, sofern das kundenseitig hinzugefügte

Umgehäuse für diesen Temperaturbereich zulässig ist.

Wenn die in 1.4 genannten Anforderungen erfüllt sind, könnte das entstehende Produkt wie

folgt gekennzeichnet werden:

II 3G Ex nA II T4 X

II 3D Ex tD A22 IP5x T80°C X

Die Sicherheitshinweise gemäß Zeichnung 940515410979-460, Revision 02 sind vom

Hersteller des Endprodukts anzupassen und zu erweitern und seinem Produkt beizulegen.

1.2 Normen

1.2.1 Normen für den Ex-Schutz

EN 60079-0: 2006 Gas: Allgemeine Anforderungen

EN60079-15:2005 Zündschutzart „n“

EN 61241-0: 2006 Staub: Allgemeine Anforderungen

EN 61241-1: 2004 Schutz durch Gehäuse „tD“

1.2.2 Einhaltung anderer Normen

Das Gerät muss die Anforderungen der EN 61010-1 für die elektrische Sicherheit erfüllen.

Ferner müssen die Anforderungen gemäß EMV-Gesetz erfüllt werden.

Installationsanleitung PR5410/03

9499 050 54304 09.11.2018 Seite 3 von 7 Seiten

1.3 Indikator PR5410/03

1.3.1 Allgemein

Der Indikator ist geeignet zum Anschluss an Gleichspannung von 24 V DC (

±

20 %). Die

Leistungsaufnahme beträgt ca. 11 W.

Abb. 1: Indikator Typ PR5410/03

Der Indikator PR5410/03 besteht aus einem Metallgehäuse (Aluminiumprofile und verzink-

tes Blech). Die Frontplatte (unter der Tastaturfolie) ist knapp 4 mm dick (Aluminium) und im

Bereich der Taster und des Sichtfensters zurückgesetzt, so dass der Impact-Test mit ver-

minderter Energie bestanden wird.

Abb. 2: Indikator Typ PR5410/03, Verstärkungsrahmen und Haltebügel

Indikator Typ

PR5410/03

Verstärkungsrahmen

Haltebügel

Installationsanleitung PR5410/03

9499 050 54304 09.11.2018 Seite 4 von 7 Seiten

Abb. 3: Versorgungsanschluss am Indikator Typ PR5410/03 mit Sicherungshalter

Abb. 4: Anschlüsse an der Gehäuserückwand des Indikators Typ PR5410/03

1.3.2 Innerer Aufbau des Indikators Typ PR5410/03

Der innere Aufbau des Indikators PR5410/03 erfüllt die relevanten Anforderungen

der Normen für den Einsatz in Zone 2 und Zone 22:

EN 60079-0: 2006 Gas: Allgemeine Anforderungen

EN60079-15:2005 Zündschutzart „n“

EN 61241-0: 2006 Staub: Allgemeine Anforderungen

EN 61241-1: 2004 Schutz durch Gehäuse „tD“

1.3.2 Einbau des Indikators Typ PR5410/03 in ein Umgehäuse gemäß Zeichnung

940515410979-510

Die am Indikator angeschraubten Haltebügel werden entfernt. Die im Montageset

940515410979-511 mitgelieferte Dichtung wird von hinten über den Indikator geschoben

und dicht gegen die Front gelegt. Dann wird der Indikator von Vorne durch den Ausschnitt

der Gehäusefront geschoben. Von Hinten wird der im Montageset 940515410979-511 mit-

gelieferte Verstärkungsrahmen geschoben und dicht an die Gehäusefront geschoben. Da-

nach werden die beiden Haltebügel wieder angeschraubt, die beim Festschrauben gegen

den Verstärkungsrahmen drücken, so dass dieser die Front des Indikators gegen die Ge-

häusefront presst.

Angabe Sicherungswert

Sicherungshalter

Anschluss

Wägezellen

Installationsanleitung PR5410/03

9499 050 54304 09.11.2018 Seite 5 von 7 Seiten

1.4 Anforderungen an ein Umgehäuse für den Indikator PR5410/03

Der Aufbau des Umgehäuses einschließlich dessen Kabeleinführungen sowie die Prüfun-

gen des Endprodukts unterliegen der alleinigen Verantwortung des Herstellers des End-

produkts.

Im Folgenden werden einige einzuhaltende Punkte genannt ohne Anspruch auf Vollstän-

digkeit.

Das äußere Gehäuse (Umgehäuse) muss so beschaffen sein, dass der IP54-Schutz ge-

währleistet wird. Dazu wird ein Gehäuse aus mind. 1 mm dickem Edelstahlgehäuse emp-

fohlen. Eine Fronttür ist über Scharniere fest mit dem übrigen Gehäuse zu verbinden. Nur

mittels Werkzeug darf dann diese Tür geöffnet werden können.

Wird ein Kunststoffgehäuse verwendet, ist auf die elektrostatische Leitfähigkeit des Ge-

häuses sowie auf seine chemische, thermische und mechanische Beständigkeit zu achten.

Der Potenzialausgleichsanschluss (PA-Anschluss) kann über Montagemittel oder über eine

intern angebrachte Erdungsklemme (Klemmleiste) erfolgen. Alle Teile (Tür, Gehäuse) sind

über Erdungskabel miteinander verbunden und damit an PA angeschlossen.

Alle Kabelverschraubungen müssen die Anforderungen für IP54 erfüllen, für einen Tempe-

raturbereich von -15 °C bis +80 °C geeignet sowie ATEX- zugelassen1 sein.

Es wird die Verwendung eines Belüftungselements empfohlen:

Typ DAE M12 SS der Firma Weidmüller GmbH & Co. KG. Es besteht aus

Edelstahl und erfüllt die Anforderungen für IP66, 68 und 69K. Es ist geeignet

für den Temperaturbereich von -40 °C bis +120 °C.

Die interne Verdrahtung im äußeren Gehäuse erfolgt durch Schrauben bzw. weist Verrie-

gelungen auf.

Dichtungen müssen eine Dauergebrauchstemperatur von mindestens 80 °C aufweisen. Auf

die chemische Beständigkeit ist zu achten und dem Endkunden mitzuteilen.

Der Einbau des Indikators PR5410/03 in das Umgehäuse muss durch den Hersteller des

Endprodukts gemäß Zeichnung 940515410979-510, Revision 01 erfolgen. Dabei sind nur

die von Minebea Intec gelieferten Montagemittel 940515410979-511 zu verwenden.

1 Z. B. Kabelverschraubung „blueglobe® Ex e II“ der Firma PFLITSCH GmbH & Co. KG: „II 2 G/D, Ex e II“; PTB

06 ATEX 1036 X, IP 68; Messing vernickelt; M16: Art.-Nr. bg 216msex; M20: Art.-Nr. bg 220msex. Tempera-

turbereich des Dichteinsatzes: -40 °C bis +105 °C. Alternativ: Kabelverschraubungen Typ Perfect*** der Firma

Jacob GmbH; DMT 99 ATEX E 016 (4. Nachtrag); II 2G Ex e / II 2D Ex td A21 IP68; Temperaturbereich -20°C

... +80°C.

Installationsanleitung PR5410/03

9499 050 54304 09.11.2018 Seite 6 von 7 Seiten

2. Hinweise zum Schutzkonzept

2.1 Staubexplosionsschutz

Die Anforderungen für Zone 22 gemäß EN 61241-0: 2006 und EN 61241-1: 2004 sind

erfüllt:

2.1.1 Das Umgehäuse des Indikators muss mindestens IP65 genügen. Die mechanische Festig-

keit ist im Allgemeinen durch das Metallgehäuse realisiert. Die nichtmetallischen Teile (Fo-

lientastatur) bestehen den Impact-Test (1 kg aus 0,7 m Höhe). Alle eingeführten Kabel

müssen den Zugtest von 100 N (10 kg) über 6 h (Auszug <6 mm) bestehen.

2.1.3 Die Oberflächentemperatur des Indikators PR5410/03 beträgt im Normalbetrieb unter ma-

ximaler Belastung und bei einer maximal erlaubten Umgebungstemperatur von +40 °C we-

niger als 55 °C und damit weniger als 60 °C (5 K Sicherheitszuschlag). T80 °C ist damit

eingehalten.

2.1.2 Die Dauergebrauchstemperaturen der Dichtungen, Kabelverschraubungen und Belüf-

tungselement müssen mindestens 10 K höher als die maximale Gehäusetemperatur bei

maximaler zulässiger Umgebungstemperatur betragen, also mindestens 70 °C.

2.1.4 Die Erdung (Potenzialausgleichsanschluss) soll über eine im Gehäuse angebrachte

Schraube bzw. über Montagemittel erfolgen.

2.1.5 Zur Vermeidung von Zündgefahren durch elektrostatische Aufladung ist die Oberfläche der

Folientastatur kleiner 180 cm² und von einem geerdeten Rahmen umgeben. Zudem ist die

Dicke der Polyesterfolie auf 180 µm begrenzt und die Folientastatur auf geerdeter Front-

platte geklebt. Ladung kann also abfließen. Ferner ist die Tastatur keiner permanenten

Reibung ausgesetzt, so dass keine Gefahr der Staubexplosion besteht.

2.2 Gasexplosionsschutz

Für die Zone 2 kommen folgende Anforderungen der EN 60079-15:2005 hinzu:

2.2.1 Der Indikator enthält keine funkengebenden Teile. Die Schutzart Ex nA wird erfüllt. Aus-

nahme ist die Tastatur, die einen energiebegrenzten Stromkreis Ex nL enthält.

2.2.2 Das Gerät gilt als spannungs- und leistungsbegrenzt (≤30 V; 11 W). Auswirkungen von

Transienten werden verhindert. Damit müssen aufgrund von Kapitel 23 der EN60079-

15:2005 die Kapitel 6.7 (Luft- und Kriechstrecken und Abstände) und 6.8.2 (Isolierung zwi-

schen leitfähigen Teilen) der EN60079-15:2005 nicht berücksichtigt werden!

2.2.3 Alle Kabel (außer 24 V DC-Versorgungskabel) sind Datensignalleitungen, so dass für diese

keine Transienten zu berücksichtigen sind.

2.2.4 Die eingebaute Batterie ist vom Typ 1 und erfüllt die Anforderungen nach Kapitel 22 der

EN 60079-15:2005.

2.2.5 Die Tastatur wird als Ex nL eingestuft (energiebegrenzter Stromkreis).

2.2.6 Alle Platinen sind fest angeschraubt.

2.2.7 Die Schnittstellenkarten enthalten nur nA – Stromkreise, es sind keine Trafos, Batterien,

Relais oder andere funkengebende oder spannungserzeugende Bauteile auf den Karten

vorhanden. Kodierschalter sind hochohmig angeschlossen (Ex nL –Stromkreise). Bauteile

müssen so bemessen sein, dass im Normalbetrieb keine Temperaturerhöhung auf mehr

als 80 °C auftreten kann. Die angeschlossenen Geräte liefern über die Datenleitungen nur

Spannungen und Leistungen, die die Anforderungen aus Kapitel 23 der EN60079-15:2005

erfüllen.

2.2.8 Zur Vermeidung von Zündgefahren durch elektrostatische Aufladung ist die Oberfläche der

Tastaturfolie kleiner 180 cm² und von einem geerdeten Rahmen umgeben. Zudem ist die

Dicke der Polyesterfolie auf 180 µm begrenzt und die Folientastatur auf geerdeter Front-

platte geklebt. Damit sind Gase der Gruppe IIC zulässig.

2.2.9 Es sind Sicherheitsreserven vorhanden.

Installationsanleitung PR5410/03

9499 050 54304 09.11.2018 Seite 7 von 7 Seiten

3. Verifizierung der Übereinstimmung mit EN 60079-15:2005

Die Übereinstimmung des Indikators PR5410/03 mit EN 60079-15:2005 wird durch die

Minebea Intec GmbH bestätigt. Werden die Maßnahmen gemäß Kapitel 2.2 umgesetzt

und erfolgt die Montage gemäß 1.3.2, so kann der Hersteller des Endprodukts die

Gesamtkonformität erstellen.

4. Verifizierung der Übereinstimmung mit EN 50281-1-1:1998

Die Übereinstimmung des Indikators PR5410/03 mit EN 50281-1-1:1998 wird durch die

Minebea Intec GmbH bestätigt. Werden die Maßnahmen gemäß Kapitel 2.2 umgesetzt und

erfolgt die Montage gemäß 1.3.2, so kann der Hersteller des Endprodukts die Gesamtkon-

formität erstellen.

5. Prüfungen

Die für das Umgehäuse von den unter 3. und 4. genannten Normen verlangten Prüfungen

sind vom Hersteller des Endprodukts durchzuführen.

6. Interne Fertigungskontrolle gemäß Richtlinie 94/9/EG

Der Hersteller des Endprodukts muss eine interne Fertigungskontrolle gemäß Anhang VIII

der Richtlinie 94/9/EG durchführen.

7. Dokumentation

Dem Produkt muss eine Betriebsanleitung beigefügt werden, die alle sicherheitsrelevanten

Informationen beinhaltet.

Eine EG-Konformitätserklärung ist dem Produkt beizulegen, aus dem auch die technischen

Daten hervorgehen und welches auf die Sicherheitshinweise verweist, da das Gerät mit „X“

gekennzeichnet wird.

Die Sicherheitshinweise gemäß Zeichnung 940515410979-460, Revision 02 sind vom

Hersteller des Endprodukts anzupassen und zu erweitern und seinem Produkt beizulegen.

Published by

Minebea Intec GmbH | Meiendorfer Strasse 205 A | 22145 Hamburg, Germany

Phone: +49.40.67960.303 | Email: [email protected]

www.minebea-intec.com

-

1

1

-

2

2

-

3

3

-

4

4

-

5

5

-

6

6

-

7

7

-

8

8

-

9

9

-

10

10

-

11

11

-

12

12

-

13

13

-

14

14

-

15

15

-

16

16

Minebea Intec PR 5410/03 Installationsanleitung

- Typ

- Installationsanleitung

in anderen Sprachen

Verwandte Papiere

-

Minebea Intec Intrinsically Safe Input/Output Interface Bedienungsanleitung

Minebea Intec Intrinsically Safe Input/Output Interface Bedienungsanleitung

-

Minebea Intec Pallet Scale/Flat-bed Scale: Option Y2 for Use in Zone 2 and 22 Hazardous Areas Bedienungsanleitung

Minebea Intec Pallet Scale/Flat-bed Scale: Option Y2 for Use in Zone 2 and 22 Hazardous Areas Bedienungsanleitung

-

Minebea Intec Combics Option Y2 Models CAIS… | CAW.S… | CAAP… Combics Equipment for Use in Zone 2 and 22 Hazardous Areas Bedienungsanleitung

Minebea Intec Combics Option Y2 Models CAIS… | CAW.S… | CAAP… Combics Equipment for Use in Zone 2 and 22 Hazardous Areas Bedienungsanleitung

-

Minebea Intec YRB02-X Ex Rechargeable Battery Pack Bedienungsanleitung

Minebea Intec YRB02-X Ex Rechargeable Battery Pack Bedienungsanleitung

-

Minebea Intec Remote display PR 5110/60, ../70 Bedienungsanleitung

Minebea Intec Remote display PR 5110/60, ../70 Bedienungsanleitung

-

Minebea Intec IU... Palettenwaage Bedienungsanleitung

Minebea Intec IU... Palettenwaage Bedienungsanleitung

-

Minebea Intec Y2 option for PR 5230 Bedienungsanleitung

Minebea Intec Y2 option for PR 5230 Bedienungsanleitung

-

Minebea Intec Ex Remote Terminal for Maxxis 5 Bedienungsanleitung

Minebea Intec Ex Remote Terminal for Maxxis 5 Bedienungsanleitung

-

Minebea Intec YPS02-XV24 Power Supply for Installation in Hazardous Areas Bedienungsanleitung

Minebea Intec YPS02-XV24 Power Supply for Installation in Hazardous Areas Bedienungsanleitung

-

Minebea Intec Signum: Option Y2 Einsatz in explosionsgefährdeten Bereichen der Zone 2 und 22 Bedienungsanleitung

Minebea Intec Signum: Option Y2 Einsatz in explosionsgefährdeten Bereichen der Zone 2 und 22 Bedienungsanleitung