Outline

3. Mounting bore for sensor

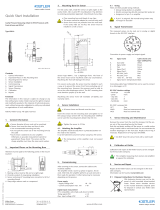

For even cavity wall, mount the sensor at right angles to the

cavity. In hardened tool steel erode, mill or grind the H7-bore.

Note the centering and the alignment. Clean the threads free

of chips.

• Clean the mounting bore and the threads free of chips

• This sensor cannot be adapted to the contour!

Quick Start Installation

Cavity pressure sensor for low viscosity resins with ø4 mm

Front

Type 6165A… (4 pC/bar, 200 bar, 200 °C)

1. General information

• Sensor diameter ø4 mm should not be machined

• The sensor front must be clean and without any

notches

• Use only the mounting socket recommended

• Do not pull on the cable to extract the sensor from

the bore

6165A_002-796e-03.18

Contents

1. General information

2. Critical points of the mounting bore

3. Mounting bore for sensor

4. Cable channeling and connector

5. Mounting the sensor

6. Installing cable connector

7. Mounting the nameplate

8. Functional test

9. Service and repairs

Foreword

Information in this document is subject to change without notice.

Kistler reserves the right to change or improve its products and

make changes in the content without obligation to notify any

person or organization of such changes or improvements.

© 2017 ... 2018 Kistler Group. All rights reserved. Kistler

Group products are protected by various intellectual property

rights. For more details visit www.kistler.com.

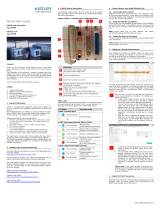

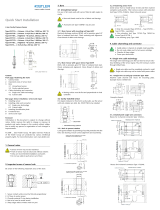

1. The bearing surface is flat and at right angles

2. The bevel protects the O-ring during mounting

3. Sensor centering in H7-bore is concentric to the mounting

thread M6

4. Sharp edge reduces the mark on the component

The Type 6165A... sensor has a diaphragm front. The front of

this sensor should not be machined under any circumstances.

Machining the front will damage the sensor.

Machining the sensor front shall invalidate all liability and

warranty claims!

• Sensorfront must not be machined

2. Critical points of the mounting bore

The following points in the bore must be watched:

A

3

2

4

1

0,01 A

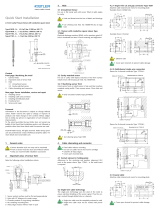

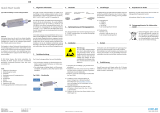

Type 1645C__

Kabel *

5

13

KIAG M4 pos.

2

O-Ring *

Type 1100A63

Kabel / cable

SW5,5

Type 1645C_

Sensor Typ 6165AA__

Massbild / Dimension drawing

O-Ring

Type 1100A57

6

4 g6

M5

2

13

L=...m

0

4-

5

0,012

0,004

-

-

M6

6,2

16,25

14,2

0,05

4,9 g7 -

-0,004

0,016

Sensor Typ 6165AAE / 6165AAG

Massbild / Dimension drawing

Kabel / cable

Type 1666A_

5

M5

0,97

L=1,5 m

* optionales Zubehör

Einbaubohrung

Mounting bore

M6

4,7

0,012

0

min.

5,5

7,5

4±0,02

0,2

4 H7 +

5,1 ±0,03

60°

Massbild / Dimension drawing

Sensor Typ 6165AA

200 °C

19,7

KIAG M4 neg.

öffentlich

Bik siehe Tabelle

Cadenas, 6165A_

a

100014613

Beo

26.01.2017

25.08.2016

100.262.345

26.01.2017

1 / 1

ges.

WZ-Dr-Sensor D4

Bl.

3:2

measure. analyze. innovate.

Erstmals verwendet

Erste Proj.-Nr.

Werkstoff

Änderung Datum Massstab

Ersatz für Kopie Datum

gez.

gepr. Hs

26.01.2017

Cau

Material-Nr.

26.01.2017

Zeichnungs-Nr.

A4

KIWAG-SWX_A4h

Ver.

Das Urheberrecht an dieser Zeichnung, die dem Empfänger

persönlich anvertraut wird, verbleibt unserer Firma.

Ohne unsere schriftliche Genehmigung darf die Zeichnung

weder kopiert noch vervielfältigt, noch an Drittpersonen

mitgeteilt oder zugänglich gemacht werden.

6165A_ _

0,2 mit PFA-Kabel D2, Typ 1645C0,2, L=0,2 m

0,4 mit PFA-Kabel D2, Typ 1645C0,4, L=0,4 m

0,6 mit PFA-Kabel D2, Typ 1645C0,6, L=0,6 m

0,8 mit PFA-Kabel D2, Typ 1645C0,8, L=0,8 m

1,2 mit PFA-Kabel D2, Typ 1645C1,2, L=1,2 m

1,6 mit PFA-Kabel D2, Typ 1645C1,2, L=1,6 m

sp mit PFA-Kabel D2, Typ 1645Csp, L=… m

Emit Single-Wire Kabel L=1,5 m

(mit Stecker Typ 1839 im Lieferumfang)

Gmit Single-Wire Kabel L=1,5 m

(ohne Stecker Typ 1839 im Lieferumfang)

Abis 200°C

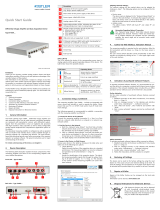

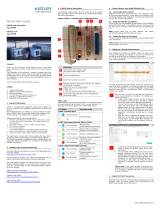

5. Mounting the sensor

• All sensor bores and threads must be clean

• Radial curves in the channels and at transitions

prevent damage to the cables

Insert the sensor in the thread of the mounting bore. Use

mounting tool Type 1700A177 to hand tighten it with a 3-5

Nm torque.

• Hand-tighten with a 3-5 N.m torque

• Use the Type 1300A177 mounting tool

6. Installing cable and connector

• Check again that edges of cable duct and hole are

chamfered

• Use a metal plate to cover open ducts/slots

• Attach cap and place on connector

6.1 Single-wire technology

• Single-wire cable must be completely enclosed in

the mold

• Single-wire cable may not be routed with power

cables

• Ensure that all contact surfaces and threads are

clean and dry

Kistler Group

Eulachstrasse 22

8408 Winterthur, Schweiz

Tel. +41 52 224 11 11

Fax +41 52 224 14 14

info@kistler.com www.kistler.com

6165A_002-796e-03.18 © 2017 ... 2018 Kistler Group

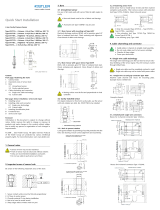

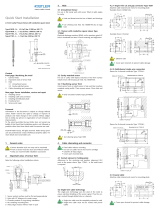

4 H7

+

0,012

0

4

±0,02

5,5

4,7

0,2

60°

M6

5,1

±0,03

min.

7,5

min. 29,4

SW5,5

Einbaubeispiel 6165A_

A4

0

1 / 1

3:2

measure. analyze. innovate.

Erstmals verwendet

Erste Proj.-Nr.

Werkstoff

Änderung

Datum

Massstab

Ersatz für

Kopie Datum

100014613 20.01.2017

gez.

gepr.

ges.

20.01.2017

Beo

100.268.757

Zeichnungs-Nr.

Material-Nr.

KIWAG-SWX_A4h

Ver.

Bl.

interne und externe Fertigung

Das Urheberrecht an dieser Zeichnung, die dem Empfänger

persönlich anvertraut wird, verbleibt unserer Firma.

Ohne unsere schriftliche Genehmigung darf die Zeichnung

weder kopiert noch vervielfältigt, noch an Drittpersonen

mitgeteilt oder zugänglich gemacht werden.

4. Cable channeling and connector

• Fixed cable reduces mounting

• Do not run cables next to hot runner cartridge

• Chamfer all sharp edges

• Cover open channels/slots

4.1 Cable technology

The single-wire technology uses the tool steel to ensure elec-

trical shielding of the sensor signal. Thus the wiring is routed

through drilled holes or channels.

• Single-wire cable must be completely enclosed in mold

• Single-wire cable must not be routed with power

cables

4.1.1 Single channel connector: single-wire Type 1839

Machine cable channel and recess for mounting plate.

Example shown: Drilled hole.

4.1.2 Multi channel connectors: single-wire or coaxial

Recess for 4-channel connector Type 1722A…

• Observe radii

• Cover open channels to prevent cable damage

Example shown: channel

Recess for 8-channel connector Type 1722A…

Outline

4.1.3 Single channel connector: coaxial

Machine cable channel and recess for mounting plate.

• Cover open channel to prevent cable damage

Kistler Group

Eulachstrasse 22

8408 Winterthur, Schweiz

Tel. +41 52 224 11 11

Fax +41 52 224 14 14

info@kistler.com www.kistler.com

6165A_002-796e-03.18 © 2017 ... 2018 Kistler Group

7. Mounting the nameplate

Rivet the nameplate to the side of the tool or mount it using

four M2.5 screws.

8. Functional test

Once the tool is assembled completely, check the insulation

of the sensor in the assembled state.

• Make sure all connectors are dry

• Use Type 1003 cleaning spray

8.1 Insulation check

Check the insulation of the sensor using the Type 5495

insulation tester. Insulation resistance >1013 Ω.

8.2 Check the function of the sensor

Test the sensitivity of the installed sensor using Test Set Type

5495.

Approx. measured value: 4 pC

• Use adaptor type 55124493 for testing, as the

diaphrame can be destroyed without it.

9. Service and repairs

Piezoelectric pressure sensors are maintenance-free. Insulati-

on and sensitivity of the installed sensor should, however, be

checked after each mold maintenace.

• Ensure that connector is dry

• Cover sensor hole during cleaning

• Use cleaning spray Type 1003

9.1 Insulation test

See chapter 8.1

9.2 Sensor functional check

See chapter 8.2

9.3 Removing sensor

Untighten sensor with mounting tool Type 1300B12Q01

and remove it from the mounting bore.

• Do not use a hammer on the sensor front

• Do not use a sharp center punch

9.4 Dismounting of cables

Fix Sensor with fork wrench AF5.5 and detach cable with

fork wrench AF 4 / AF 5 Type 5.210.164.

9.5 Single-wire repair

Slightly damaged cables can be repaired using the Repair Kit

Type 1207. If single-wire cables have been severed, solder

ends, slide over Teflon tube and cover with shrink tubing.

• Do not overheat sensor and cable when using

hot air blower

9.6 Repairs at Kistler

Factory repairs at Kistler are arranged by the local sales office

Information: www.kistler.com

9.7 Disposal instructions for electrical and electronic

equipment

Do not discard old electronic instruments

in municipal trash. For disposal at end of

life, please return this product to an autho-

rized local electronic waste disposal service

or contact the nearest Kistler Instrument

sales office for return instructions.

6.1.1 Cut & grip connection

Cut the single-wire cable to length and do not strip the insu-

lation. Open connector by hand, insert the single-wire cable

and close it again.

6.1.2 Installing single-wire connector

Install connector and mounting plate in recess. Attach cap

using one of the screws. Place cap on open connector.

Installation of connector Type 1839 and mounting plate

Installation of multichannel connector

Example: Type 1722A4...

6.2 Coaxial cable

6.2.1 Installation of coaxial connector

Install connector and mounting plate in recess. Attach cap

using one of the screws. Place cap on open connector.

-

1

1

-

2

2

in anderen Sprachen

- English: Kistler 6165AA Quick start guide

Verwandte Artikel

-

Kistler 4001A202FA2,0 Schnellstartanleitung

Kistler 4001A202FA2,0 Schnellstartanleitung

-

Kistler 6178C Schnellstartanleitung

Kistler 6178C Schnellstartanleitung

-

Kistler 5166A Schnellstartanleitung

Kistler 5166A Schnellstartanleitung

-

Kistler 6177B Schnellstartanleitung

Kistler 6177B Schnellstartanleitung

-

Kistler 5189A Schnellstartanleitung

Kistler 5189A Schnellstartanleitung

-

Kistler 1710B1 Bedienungsanleitung

Kistler 1710B1 Bedienungsanleitung

-

Kistler 1207 Schnellstartanleitung

Kistler 1207 Schnellstartanleitung

-

Kistler 5514A21D1 Schnellstartanleitung

Kistler 5514A21D1 Schnellstartanleitung

-

Kistler 4049B Bedienungsanleitung

Kistler 4049B Bedienungsanleitung

-

Kistler 4624AK Bedienungsanleitung

Kistler 4624AK Bedienungsanleitung