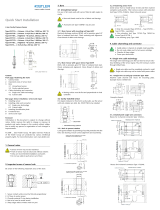

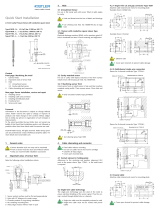

3. Mounting Bore for Sensor

For flat cavity walls, install the sensor at right angles to the

cavity. Erode, mill, or grind H7 mounting bore. Pay attention

to centering and position alignment. Clear thread of any chips.

• Clear mounting bore and thread of any chips

• This sensor cannot be adapted to a curved cavity wall!

• Sensor front must not protrude from the mold wall.

If the cavity walls are not flat, the sensor must be

installed in a with a recess

Quick Start Installation

Cavity Pressure Measuring Chain for RTM Processes with

Front ø9 mm and M12x1

Type 4001A

1. General Information

• Sensor diameter ø9 mm must not be machined

• Sensor front must be clean and free of nicks

• Use recommended mounting tool only

• Do not pull the sensor out of the mounting bore by

the cable

• Each sensor is tailored to its own amplifier.

Otherwise an accurate measurement cannot be

guaranteed. Please check: The sensor and the

charge amplifier must have the same serial number.

4001A_002-782e-06.16

Contents

1. General Information

2. Important Places on the Mounting Bore

3. Mounting Bore for Sensor

4. Sensor Installation

5. Commissioning

6. Signal Transmission

7. Sensor Cleaning

8. Calibration

9. Repairs

Foreword

The information in this manual is subject to change at any

time without prior notice. Kistler reserves the right to improve

and modify this product in the interests of technical advance-

ment without being under obligation to notify any individuals

or organizations of such

modifications.

©2016, Kistler Group. All rights reserved.

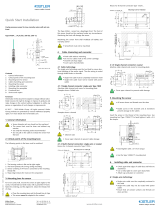

1. Bearing surface must be flat and at a right angle

2. Chamfer protects O-ring during installation

3. Sensor centering H7 mounting bore concentric to M12x1

mounting thread

4. Sharp edge reduces mark on component

Sensor Type 4001A... has a diaphragm front. The front of

this sensor must not be machined under any circumstances.

Machining the front will damage the sensor.

For uneven cavity walls, the sensor must be installed in such

a way as to prevent the sensor front from protruding out of

the mounting bore. However, the pressure must be able to

act on the entire diaphragm surface. The 9H7 mounting bore

must therefore project up to the wall.

Machining the sensor front will invalidate all liability and

warranty claims.

2. Important Places on the Mounting Bore

Attention must be paid to the following points on the mount-

ing bore:

A

3

2

4

1

0,01 A

A

3

2

4

1

0,01 A

12

R

min.35

Min. 90 (bei abgedeckten Einbau)

6 *

0

min.

20

0,015

0

+

9 H7

+0

0,2

13

M12x1

20

11 H7 +0,018

0,4x30°

öffentlich

Material-Nr.

Ver.

Zusammenstellung Einbau 4001A

100.251.696

gepr.

ges.

KIWAG-SWX_A4h

01 / 1

1:3

measure. analyze. innovate.

Erstmals verwendet

Erste Proj.-Nr.

Werkstoff

Änderung Datum Massstab

Ersatz für Kopie Datum

18030846 4001A

A4 Bl.

19.01.2016 Beo

gez.

Zeichnungs-Nr.

Das Urheberrecht an dieser Zeichnung, die dem Empfänger

persönlich anvertraut wird, verbleibt unserer Firma.

Ohne unsere schriftliche Genehmigung darf die Zeichnung

weder kopiert noch vervielfältigt, noch an Drittpersonen

mitgeteilt oder zugänglich gemacht werden.

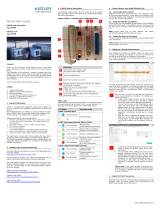

4. Sensor Installation

• All sensor bores and threads must be clean

Insert the sensor into the mounting bore and tighten to 10

Nm using a torque wrench (AF 12). Mounting tool 1300A42

can be used for mounting bores deeper than 30 mm.

• Tighten the sensor to 10 Nm

4.1. Attaching the Amplifier

The amplifier should be attached in a protected position on

the mold or the machine.

It can be fastened to any level surface using four M4 screws.

• The temperature at the amplifier must not exceed

75°C.

7. Sensor Cleaning and Maintenance

Remove the sensor from the mold for cleaning. Pull the sen-

sor out of the mounting bore by the thread.

Rub dirt and plastic residues off the sensor in a radial motion

using a leather cloth or soft brass brush. Do not overstrain the

sensitive diaphragm on the front face. Replace the O-ring if

necessary. Replacement O-ring Type 55139386.

• Do NOT clean the sensor front with a steel brush!

5. Commissioning

After screwing in the sensor, connect the cable to the

matched amplifier.

The amplifier needs a warm-up phase of approx. 30 sec-

onds. After that, the amplifier performs an auto tare and is

then ready for operation. Further taring may be necessary

depending on the process.

Power supply

- Supply voltage VDC 18 ... 30

- Current consumption max. mA < 40

Digital input measurement

(TTL compatible, active high, pull-down to GND)

Taring signal VDC > 3.2

Max. input voltage VDC ± 30

8. Calibration at Kistler

Calibration and repairs at the Kistler factory can be arranged

via the local sales company.

• The complete measuring chain (sensor and amplifier)

is required for calibration

Kistler Group

Eulachstrasse 22

8408 Winterthur, Switzerland

Tel. +41 52 224 11 11

Fax +41 52 224 14 14

info@kistler.com www.kistler.com

6. Signal Transmission

The measured values can be read out in analog or digital

format via the RS-232C interface.

9. Service and Repair

Repairs at the Kistler factory can be arranged via the local

sales company.

Information can be found at www.kistler.com

9.1 Disposal Instructions for Electronic Devices

Old electronics devices may not be dis-

posed of with household refuse/residual

waste. Please return obsolete devices

to the nearest electronics disposal point

for disposal or contact your Kistler sales

representative.

4001A_002-782e-06.16 ©2016, Kistler Group

Das Urheberrecht an dieser Zeichnung, die dem Empfänger per-

sönlich anvertraut wird, verbleibt unserer Firma. Ohne unsere

schriftliche Genehmigung darf die Zeichnung weder kopiert noch

vervielfältigt, noch an Drittpersonen mitgeteilt oder zugänglich ge-

macht werden.

öffentlich

Änderung

100010632-T1

Datum

26.01.2016

Erzeugersystem

Word 2010

Europäische

Projektion

Erste Proj.-Nr.

Kopie Datum

Niederdruck-Messkette

Spezifikations - Kontrollblatt

gez.

22.01.2016

Beo

kISTLER

Format

A4

Dokumentnummer

Version

n

Blatt 1

gepr.

25.01.2016

Cau

4001A___-01

b

Kistler Instrumente AG, Winterthur

Switzerland

von 5

ges.

25.01.2016

Hs

Kurzbeschreibung

Die piezoresistive 3-Kanal Niederdruck- Messkette mit integriertem Brückenverstärker eignet sich

besonders zur Messung vom statischen Werkzeuginnendruck beim Spritzgiessen von niederviskosen

Kunststoffen bis 250°C. Typische Anwendung ist die Forminnendruckmessung beim RTM Prozess.

Hauptmerkmal

Statisch messend von -1…50 bar, Temperaturkompensiert

Hoher Temperaturbereich bis 250°C mit Temperaturausgang 10mV/K

Einfache Montage und IP 65 für den industriellen Einsatz

Zwei frei programierbare, unabhängige Messbereiche

Autokalibration auf Maschine über RS232 Befehl

Manueller Tariertaster

Das Gerät ist im Sinne der EG Richtlinie 2004/108/EG conform und erfüllt die EMV Normen:

EN 61000-6-4 und EN 61000-6-2 Störfestigkeit Produktenorm: EN61326-1 (Klasse A)

4001A___-01 - b - YS0 - SKB - öffentlich - Freigegeben --- siehe Tabelle --- 20-Jun-2016 05:48 (CET) - [email protected]

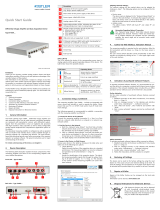

Connection to power supply and output signals

Pin Signal name Cable strand color

Type 1200A227A2

A Exct GND White

B Signal GND Brown

C Tara Green

D Signal Out 1 Yellow

E Signal Out 2 Gray

F RS-232C_RxD Pink

G RS-232C_TxD Blue

H +Exct 18 … 30 VDC Red

J Signal Out 3 (temperature) Black

Connecting cable Type 1200A227A2 can be used to connect

to a data logger or PC.

RS-232C interface settings

- baud bps 115,200

- parity none

- stop bits 1

- data bits 8

- handshake none

RS-232C command list:

:SCT Tare

:RMD Read out measurement data

:RCD Read out control data

5.1 Taring

There are three possible taring methods.

• Manual taring button on amplifier

• RS-232 command (see RS-232 command list, Section 6)

• Assignment of pin C on amplifier

• If pin C is assigned, the manual taring button may

no longer be actuated

-

1

1

Kistler 4001A510FA2,0 Schnellstartanleitung

- Typ

- Schnellstartanleitung

- Dieses Handbuch eignet sich auch für

in anderen Sprachen

Verwandte Artikel

Andere Dokumente

-

HBM WI/2mm-T Mounting instructions

-

Baumer DABU MP4M Bedienungsanleitung

-

WIKA DI35 Bedienungsanleitung

-

SICK MAX Quickstart

-

Baumer DACU 800-0.0-1K0-BS Installation and Operating Instructions

-

Baumer FOC 500C6Y00 Bedienungsanleitung

-

SICK POMUX KH53 / POMUX KH53 Advanced Bedienungsanleitung

-

Baumer FSL 500C6Y00 Bedienungsanleitung

-

Denver Instrument Summit SI-4001 Bedienungsanleitung

Denver Instrument Summit SI-4001 Bedienungsanleitung

-

KERN PBS 620-3M Bedienungsanleitung